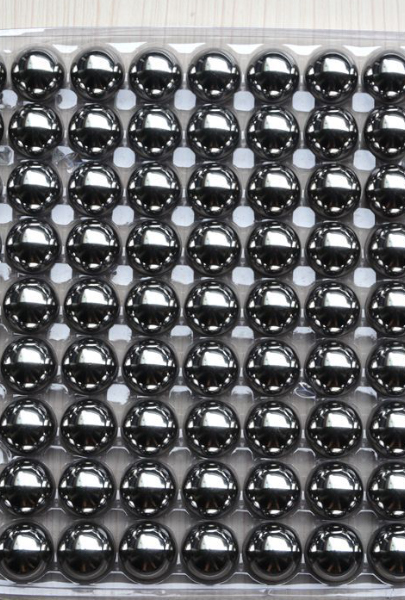

Ball bearing balls are smooth round balls used in bearings: most commonly used in ball bearings, flange bearings, thrust roller ball bearings, angular contact bearings, auto bearings.Bearing balls come in different sizes and materials: usually bearing steel, stainless steel, ceramic. 2023 China produces 27.5 billion sets of bearings. Stainless steel, ceramic.

Table of Contents

Ball Bearing Ball Basics

Ball bearing balls are an important component of many modern machines and equipment and play a particularly crucial role in reducing friction and increasing efficiency. Whether it is industrial machinery or consumer goods, ball bearings are an indispensable part of our daily lives.

What is a ball bearing balls? A ball bearing is a rolling element consisting of one or more rows of balls separated by a cage assembly. The balls are generally made of steel or ceramic materials designed to rotate smoothly in the bearing. There are many different ball bearings, such as flange bearings, deep groove ball bearings, thrust ball bearings, and self-aligning ball bearings.

Innovative materials used in modern ball bearing balls.

Traditional ball bearing materials: stainless steel and bearing steel

The steel balls in bearings must be of the same size, have an extremely smooth surface, and need to work stably under a certain pressure. The surface must not be visibly worn, so it can be said that the manufacture of steel balls has very high requirements for materials and processing precision.

Bearing steel is one of the materials commonly used in ball bearings and is mainly made of high-carbon chrome steel. Guideway balls made of chrome steel have high strength and good toughness and are well adapted to applications subject to shock and vibration forces. However, chrome steel material corrosion resistance is poor, and not suitable for use in some harsh environments.

Used in the manufacture of ball steel on the “extraordinary”: it is not ordinary steel but contains chromium metal high chromium steel, chromium after the steel, change its easy to rust, easy to break the lack of, become not easy to deformation, high wear resistance, but also corrosion-resistant. Used to make everyday and high pressure and high grinding ball is undoubtedly the best choice.

Stainless steel ball bearings are relative to the bearing steel, with rust, corrosion resistance, and other characteristics, so it is suitable for use in humidity, high temperature, acid and alkali, and other harsh environments. However, the strength and hardness of stainless steel are relatively low, and the fatigue resistance life is shorter than bearing steel’s

Advanced materials for ball bearing balls: ceramics, tungsten carbide.

Scientists are always researching alternative materials for ball bearing balls. One of these materials is ceramic, which has gained popularity in the market because it is stronger, more wear-resistant, and has less friction. Ceramic ball bearings are generally used in high-speed applications where bearing steel and stainless steel cannot fulfill the requirements.

Tungsten carbide is another advanced material being developed for use in ball bearing balls. This hard and wear-resistant material has a higher melting point than ceramics, making it suitable for extreme temperature conditions.

High Quality Bearing Balls,High Quality & Timely Service,We are looking forward to your contact.

Dimensions and characteristics of bearing balls.

The specifications of bearing steel beads include diameter, hardness, and precision. The following are common specifications:

Diameter: the diameter of bearing steel beads is usually between 1mm and 50mm, of which the most common specifications are 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 18mm, 20mm, 25mm, 30mm, 40mm, 50mm and so on.

Hardness: The hardness of bearing steel balls is generally measured by HRC (Rockwell hardness), and common hardness specifications include 60HRC, 62HRC, 64HRC, 66HRC, 68HRC, 70HRC and so on. Higher hardness means higher strength and better wear resistance, but it may also lead to easier fatigue.

Accuracy: The accuracy of bearing steel balls is measured by the ABEC (American Bearing Manufacturers Association) grade.

Common grades are ABEC-1, ABEC-3, ABEC-5, ABEC-7, and ABEC-9. Higher precision means smoother and more reliable bearing operation.

The larger the diameter and hardness of the bearing beads, the greater the load they can withstand. Therefore, the size of the load to be borne should be considered when choosing the specifications of bearing steel beads. The size and quality of the bearing balls affect the rotational speed of the bearing. When the rotational speed is higher, it is necessary to choose smaller bearing balls. In high-speed, high-load, high-precision applications, it is essential to select a higher-precision bearing ball.

Commonly used mechanical bearing steel ball diameter ranges from 0.5mm to 60mm.

Among them, the steel ball with a diameter of 0.5mm12 mm is mainly used for small bearings, the ball with a diameter of 13mm28 mm is mainly used for small and medium-sized bearings, and the ball with a diameter of 30mm60 mm is mainly used for large bearings.

Balls in automotive wheel bearings.

Ball size and load carrying capacity

The size of the balls inside a wheel bearing directly affects its load-carrying capacity. Larger balls can carry heavier loads than smaller balls, which are used in heavy vehicles such as trucks, vans, or buses. Smaller balls are more suitable for lighter vehicles such as cars.

To balance performance and economy, the size of the balls is expertly designed to balance the trade-off between strength and durability. For example, a bearing with larger balls may wear more easily due to increased friction, but it can also withstand greater loads.

Hardness of ball bearing balls: a key factor in bearing performance

The hardness of ball bearing balls is another key factor in the performance of wheel bearings. Ball bearing balls must be hard enough to withstand wear and tear during use while retaining their shape under a variety of loading conditions and even overloads. If ball bearing balls are too soft, they may deform or break over time, leading to accidents.

Bearing balls utilize different types of hardness measurements, including Rockwell (RC) and Vickers hardness tests. These measurements assess a material’s resistance to deformation when subjected to an applied load. Higher RC values indicate greater hardness, while lower Vickers values indicate greater softness.

The selection of bearing balls depends on the specific application and operating conditions. For example

High-hardness balls (e.g. 90RC) are typically used for heavy-duty applications with high loads and temperatures.

Medium hardness balls (e.g., 60-80 RC) may be more suitable for light-duty vehicles or vehicles with moderate load requirements.

Heavy Duty Trucks:

These vehicles require high-load capacity wheels with large balls (e.g. 80 mm diameter) to support heavy payloads.

Highly rigid balls can withstand extreme temperatures and loads during long-distance driving or towing operations.

Passenger cars:

Smaller, lighter wheels typically use smaller steel balls (e.g., 60 mm diameter).

Medium-hardness balls provide a balance of load-carrying capacity and durability in these applications.

Bearing balls in toys.

When we think of toys, our minds are usually filled with various colorful characters, particularly engaging storylines or exciting adventures. However, there is another key component that plays a vital role in enhancing a child’s play experience: bearing balls. These little metal or plastic balls are often overlooked as an important part of toy design of all kinds.

Bearings are used in both toy cars and skateboards; bearings in toy cars need to be inexpensive because of the selling price, and bearings in skateboards tend to be more load and quality-oriented.

Among many toy bearings, 608 bearings play an important role in stroller applications. With its standard size of 8mm inner diameter, 22mm outer diameter, and 7mm height, this bearing is widely used in various stroller structures, such as spinning cars, scooter, etc.

The bearing is made of various materials, including carbon steel, bearing steel, stainless steel, etc. to meet the durability and safety requirements of different strollers. They are available in a variety of materials, including carbon steel, bearing steel, stainless steel, etc., to meet the needs of different customers for durability and safety.

Our 608 bearings have the best quality and durability, which can reduce friction and resistance during traveling, increase the life span, and also provide a safer and more comfortable riding experience for children.

Ceramic Bearings, Ceramic ball bearing balls

The development of ceramic bearings, nanomaterials, and composite materials for the development of ceramic bearings for the practical application of ceramic bearings has brought greater vitality. It can be seen that the product market gap is huge, according to our current domestic production status is far from meeting market demand. Hence, the market outlook is very favorable. In practice, the service life of ceramic bearings is heat-resistant steel bearings 5 ~ 10 times.

Ceramic materials have low density, medium modulus of elasticity, small coefficient of thermal expansion, high hardness, high temperature, corrosion resistance, non-magnetic, and other advantages; silicon nitride ceramic ball rolling body ceramic ball bearings can significantly improve the bearing contact fatigue life, greatly expanding the field of application of rolling bearings.

Silicon nitride ceramic ball bearing balls are favored in many fields mainly due to their unique performance advantages. Firstly, its high hardness and wear resistance enable the bearings to maintain stable operation when subjected to high speeds and high loads, which significantly improves the efficiency and life of the equipment.

Secondly, the low coefficient of friction helps to reduce energy consumption and wear, further improving the economy and environmental protection of the equipment. In addition, silicon nitride ceramic ball bearing balls are also resistant to high temperatures, corrosion, and good insulation, and can maintain stable performance in a variety of harsh environments, which meets the needs of high-precision, high-reliability equipment.