The various types of bearings can be categorized into eight types, depending on the look and material. The most common types of Deep Groove Ball Bearings, Flange Bearings, Thrust Roller Ball Bearings, One-Way Bearings, and Angular Contact Bearings are found in machines. v/u groove bearings, rubber coated bearings, common in furniture. and new ceramic bearings.

Table of Contents

Types of Bearings: Deep Groove Ball Bearings.

1.Introduction to Deep Groove Ball Bearings.

Deep groove ball bearings in Types of Bearings are among the most widely used and common rolling bearings. Their materials are generally stainless steel, carbon steel, bearing steel, stainless steel, plastic, and ceramics.

Deep groove ball bearings are characterized by low frictional resistance and high rotational speed, and are usually used in machinery or electrical appliances, such as electric toothbrushes, low-power electric motors, toy cars, automobile and tractor gearboxes, machine tool gearboxes, general machines, tools and so on.

With rubber seal (indicated as 2RS)

With dust cap: single or double sided metal dust cap. (indicated as ZZ)

With non-contact rubber seal: Single or double-sided non-contact seal. (denoted as 2LS)

N: Outer ring with stop groove

NR: outer ring with stop groove and stop ring.

The main materials of deep groove ball bearings include carbon steel, bearing steel, stainless steel, plastics and ceramics. Bearing rings and balls are usually made of GCR15 (AISI 52100) refined bearing steel, and the retainers are stamped from 08F high quality cold rolled steel strip. High-carbon chrome steel has excellent strength and wear resistance and is suitable for high load and high speed conditions.

Stainless steel offers excellent corrosion resistance and is commonly used in wet or chemically corrosive environments.

Ceramic materials such as alumina ceramics and silicon nitride ceramics are characterized by high strength, high hardness and low coefficient of friction, and are suitable for high-speed, high-temperature and high-precision applications.

2.Types of Bearings-Characteristics of different materials and their application scenarios.

Carbon steel: suitable for general industrial applications, inexpensive, but requires rust prevention treatment.

Bearing steel: with high hardness and wear resistance, suitable for high load and high-speed mechanical parts.

Stainless steel: with no fear of corrosion, suitable for wet or chemically corrosive environments.

Plastic: Low manufacturing price, low vibration, and low noise. Suitable for low-load and low-speed applications.

Ceramics: with high strength, high hardness, and low coefficient of friction, suitable for high-speed, high-temperature and high-precision application scenarios.

3.Structural forms and application range.

Deep groove ball bearings are available in a variety of structural forms, including bearings with dust caps and bearings with seals.

These bearings are already filled with the appropriate amount of grease, do not require heating or cleaning before mounting, do not require relubrication during use, and are suitable for operating temperatures between -30°C and +120°C.

Deep groove ball bearings are suitable for operation at high or even very high speeds, are very durable, and do not require frequent maintenance. Their structure is simple, manufacturing cost is low, easy to achieve high manufacturing accuracy.

The range of sizes and forms are varied, used in precision instruments, household appliances, toys, furniture, low-noise motors, automobiles, motorcycles general machinery, and other industries, is the most widely used class of bearings in the machinery industry.

4. Deep groove ball bearing mounting method.

Method 1: press fit: bearing inner ring and shaft to make a tight fit, outer ring, and bearing hole is a loose fit, can be used to press the bearing first pressure mounted on the shaft.

Then the shaft together with the bearing into the bearing housing hole, press-fit in the bearing inner ring end face, pad a soft metal material to do the assembly sleeve (copper or soft steel), bearing outer ring, and bearing housing hole tight fit.

Inner ring and shaft for the looser fit, the bearing can be first pressed into the bearing hole, the outer diameter of the assembly sleeve should be slightly smaller than the diameter of the seat hole.

If the bearing collar and shaft and seat hole are tight fit, the installation of the inner ring and outer ring should be pressed into the shaft and seat hole at the same time, and the structure of the assembly casing should be able to simultaneously bet on the bearing inner ring and outer ring end face.

Method 2: heating fit: by heating the bearing or bearing housing, the use of thermal expansion will change the tight fit into a loose fit installation method. Is a commonly used and labor-saving installation method.

This method is suitable for the installation of bearings with a large amount of interference before the hot installation of bearings or separable bearings of the collar into the oil tank uniformly heated 80-100 ℃, and then removed from the oil as soon as possible installed on the shaft.

In order to prevent the end face of the inner ring and the shaft shoulder from not fitting tightly after cooling, the bearing can be axially tightened again after cooling. When the outer ring of the bearing is tightly fitted with the light metal bearing housing, the hot-fitting method of heating the bearing housing is adopted to avoid abrasion of the fitted surface.

Heating bearings with an oil tank, at a certain distance from the bottom of the box, should have a mesh fence, or hooks hanging bearing, the bearing can not be put on the bottom of the box to prevent sinking impurities into the bearings or uneven heating, the oil tank must have a thermometer, strict control of the oil temperature shall not exceed 100 ° C, to prevent the occurrence of the tempering effect so that the hardness of the collar is reduced.

Types of Bearings:Flange Bearings.

1.Brief introduction of flange bearing.

Flange bearings are a common type in Types of Bearings. Also known as flanged bearings, the shape is large at one end and small at the other.

Flange bearings, also called flange coupling bearings, are a kind of special bearings, which combine the rotating function of bearings and the connecting function of flanges.

Flange bearings are generally composed of a bearing body and a flange integrated with it, so one end is small and the other is large (flange). The flange has bolt holes that can be used to mount the bearing directly to the structure of the machine or equipment.

The main advantage of flange bearings is that they are easy to mount and dismount. Because of the integrated flange, flange bearings can be bolted directly to the machine without the need for additional mounts or adapters.

Compared with other types of bearings, flange bearings not only allow fewer mounting steps and lower costs but also improve the accuracy and stability of mounting and firmness. Because of this characteristic, flange bearings have important use in many fields.

2. Application scope of flange bearings.

In the machinery manufacturing industry, flange bearings are often used in various high-speed equipment, such as motors, pumps, and fans, which are used to support and give the rotating parts positioning. In heavy industries, such as steel, mining petrochemical industry, etc.,

flange bearings are used to withstand heavy loads and high-speed working conditions, to ensure the stable operation of equipment. In addition, flange bearings are also widely used in automotive, marine, aerospace, and other fields to meet the needs of different equipment and systems.

3.Precautions for mounting flange linear bearings.

- Cleaning: Before installation, it is necessary to clean the bearings and bearing housings to ensure no residue on the surface of the parts, so as not to affect the use of the effect. Flange linear bearings are composed of several parts, especially in the installation, it is necessary to install several parts together to form the whole system, and each part of the installation position and way have to pay attention. In this case, to do a good job of installation, it is required to pay attention to distinguish all the parts, do not confuse the parts.

- Apply lubricant: Before installation, an appropriate amount of lubricant must be applied inside the bearing and on the bearing housing. This can reduce friction and wear and prolong the bearing’s life.

- To ensure that the flange linear bearings achieve the best installation status, we are required to make clear the specific operation steps before installation, and in the actual installation, strictly according to the prescribed steps, to avoid because of operation problems affecting the effect of bearing installation.

- Install the bearing: Make sure the bearing is correctly placed on the bearing housing, and then install the top cover.

- Install the flange: when installing the flange, it is necessary to correspond the flange with the bearing first, and then tighten it together with the fixing screws of the bearing housing.

- Install the seal: Finally, install the seal to prevent dust and impurities from entering the bearing.

Precautions:

- Installation must be done in the correct order, otherwise it will lead to performance degradation.

- Pay attention to the tightness of the screws, they should not be too tight or too loose.

- Be sure to apply the proper amount of lubricant to improve the service life.

- Avoid contaminants from entering into the bearing, otherwise it will lead to damage or even failure.

- After installation, the bearings should be used and maintained properly, and the lubricant should be checked and replaced regularly.

Types of Bearings:V/U groove bearings

1. Introduction to V/U Groove Bearings.

V/U groove bearings are one of the many Types of Bearings that are quite common in life. In some applications, roller bearings with grooves in the outer ring are often used, but due to their looks, these bearings are also usually referred to as pulleys. These types of bearings are often used as guide rollers, with grooves on the outer surface of the outer ring, which are available in both U-shaped grooves and V-shaped grooves to conform to the shape of their mating surfaces, and the mounting process is the same as that for standard bearings.

The grooves can be turned and ground to a mirror finish for specific applications. The basic design is the same as that of standard roller bearings (cam followers), and mounting is effortless. These bearings are often used as guide rollers for steel wires and tubes, straightening rollers, and slings for window and car cleaning.

In addition to bearings with grooves in the outer ring, there is also a types of bearings with grooves in the bearing bolts, as shown in the figure above, and this types of bearings is usually called an indexing cam follower.

When automatic machines are required to perform, for example, intermittent movements, oscillations, and continuous rotations at high speeds and with high precision, some special design is needed to perform these operations, and the indexing cam follower is born from this, and by means of the grooves in the bolts these requirements are creatively accomplished.

These bearings are the same as normal bolted roller bearings and are easily mounted with set screws, with rigid outer rings and studs that can be mounted in limited spaces. Indexing cam followers usually utilize a full complement of roller-type designs, which provide greater load-carrying capacity and longer life than cam followers with cages, and have higher dimensional and operational accuracy than conventional standards.

Types of Bearings:Thrust Roller Ball Bearings.

1. Introduction to Thrust Ball Bearings.

Thrust ball bearings are a common type of Types of Bearings, which are mainly composed of three parts: the seat ring, the shaft ring, and the steel ball cage assembly. Since the collar is cushion-shaped, thrust ball bearings are categorized into two types: flat-bottomed cushion type and self-aligning spherical cushion type. In addition, these bearings can withstand axial loads, but not radial loads.

Thrust ball bearings are generally the main material used in steel, but not all steel is suitable for this kind of mechanical hardware. Bearing steel is generally used because this will be ideal.

Bearing steel has high and uniform hardness and wear resistance, as well as a high elastic limit. The uniformity of the chemical composition of the bearing steel, the content and distribution of non-metallic inclusions, the distribution of carbides, and other requirements are very strict, and are one of the most stringent requirements of all steel production steel, but also thrust ball bearings are often used in a material.

Thrust ball bearing is a kind of separation types of bearings, the shaft ring, and seat ring can be separated from the components of cage and steel ball. The shaft ring is a collar that fits with the shaft, and the seat ring is a collar that fits with the bearing housing hole, and there is a clearance between the shaft;

Thrust ball bearings can only withstand axial load, one-way thrust ball bearings can only withstand a direction of the axial load, two-way thrust ball bearings can withstand two directions of the axial load; Thrust ball bearings can not limit the radial displacement of the shaft, the limit rotational speed is meager, the one-way thrust ball bearings can limit the shaft and the shell of a direction of the axial displacement, the two-way bearings can limit the axial displacement of two directions.

Thrust roller bearings are used to withstand axial load-oriented shaft and radial combined load, but the radial load shall not exceed 55% of the axial load. Compared with other thrust roller bearings, these bearings have a lower friction factor, and a higher speed and are self-aligning.

2. Types of Bearings-Differences between thrust roller bearings and thrust ball bearings.

Thrust roller bearings and thrust ball bearings, as two common types of thrust bearings, have significant differences in structure, load carrying capacity and use occasions. The following will be a detailed comparison of these two types of bearings:

- Structure difference

Thrust ball bearings: by the washer-shaped raceway with raceway and steel ball and cage assembly composition. Among them, the raceway ring with shaft is called shaft ring, the raceway ring with shell is called seat ring. Bidirectional bearings will be the center ring and shaft with, one-way bearings can withstand one-way axial load, two-way bearings can withstand two-way axial load (both can not withstand radial load).

Thrust roller bearings: by the collar track and roller composition, mainly by the outer ring, inner ring, roller and keep frame and other parts. Thrust roller bearings structural design so that it can simultaneously withstand the axial load and a certain radial joint load, but the radial load shall not exceed 55% of the axial load.

2.bearing capacity

Thrust ball bearings: it can withstand a certain amount of axial load, but also can withstand radial load. Its bearing capacity is relatively large, and because of the compact structure, in the same size of the equipment can provide greater installation space and bearing capacity.

Thrust roller bearings: are mainly used to withstand axial loads and have a high load carrying capacity. Compared with other thrust roller bearings, it usually has lower friction factor and higher speed, and also has self-aligning performance, which can automatically adjust the bearing position to adapt to the shaft’s small deflection or misalignment. However, the radial load carrying capacity of thrust roller bearings is relatively limited and the radial load must not exceed 55% of the axial load.

Types of Bearings:One-Way Bearings.

1. Introduction to one-way bearings

One-Way Bearings is a large category within Types of Bearings. One-way bearing is a types of bearings that is free to rotate in one direction and locks up in the other.

The metal housing of a unidirectional bearing contains several rollers, needles, or balls, and the shape of the rolling seat (cavity) is such that it can only be rolled in one direction while generating a great deal of resistance in the other direction.

Unidirectional bearings are one of the more specialized types of bearings.

2. Problems with the mounting direction of unidirectional bearings.

Regarding the installation of one-way bearings, there are many friends who have questions: should they be divided into left and right installation?

One-way bearings do not need to be divided into left and right installation. Because of the design structure of the one-way bearing itself, there is no difference between left and right, there is only one assembly direction.

In the installation of one-way bearings, it should be noted that its internal structure is different from ordinary bearings, the inner ring and the outer ring of the structure are different, therefore, the installation needs to be installed by the correct direction. Generally speaking, there is an arrow mark on the outer ring of the one-way bearing, when the arrow is the same as the installation direction, the one-way bearing can be installed correctly.

When installing one-way bearings, we need to pay attention to the following aspects:

- When installing, the one-way bearing should be pressed into the bearing housing to ensure its correct assembly.

- Attention should be paid to the direction of the one-way bearing to ensure that its arrow points in the correct direction to correctly drive the device movement.

- One-way bearings should be avoided from being subjected to shock or excessive torque during installation to prevent damage to the one-way bearings.

- While installing one-way thrust bearings, attention must be paid to the surrounding cleanliness and lubrication to keep the bearings in good running condition.

Types of Bearings:Angular Contact Bearings.

1.Introduction to Angular Contact Bearings.

An angular contact ball bearing is a kind of bearing that can withstand complex loads, which consists of the outer ring, inner ring, balls, and cage. Its balls contact the inner and outer rings at an angle of α, usually 15 degrees.

Angular contact ball bearings can withstand both axial and radial forces in one direction. The line between the upper and lower points of the rolling body force point, and the radial direction has a certain angle. Angular contact ball bearings can withstand radial and axial loads but also can withstand instantaneous large loads and high-speed rotation.

Types of Bearings:Rubber coated bearings.

1.Introduction to rubber coated bearings.

Rubber-coated bearings are special bearings in which a layer of rubber products is formed on the outer ring of the bearing by pressing or bonding using a casting or injection molding process. It is one of the common types of bearings.

Rubber-coated bearings have excellent strength, abrasion resistance, heat resistance, hydrolysis resistance, aging resistance, and bright appearance, and the surface of the gel is fine and smooth. The outer ring of the bearing is sandblasted, which makes the gel shell and core firmly bonded and not easily damaged. Rubber-coated bearings have the advantages of impact resistance and low noise compared with ordinary bearings.

2.Commonly used over-molded materials are as follows.

- polyurethane – good chemical properties, good solvent resistance, anti-aging, tear resistance, good resilience.

- Rubber – good heat resistance, cold resistance, resistance to ozone and atmospheric aging, and other properties, the disadvantage is the tensile strength and tear strength and other mechanical properties are poor, oil resistance and poor resistance to organic solvents.

- Polyacetal (POM) – with a high mechanical degree, high rigidity, high fatigue strength, good resistance to organic solvents, wear resistance is stronger, the disadvantage of poor acid resistance, molding shrinkage, long time high temperature is easy to decompose.

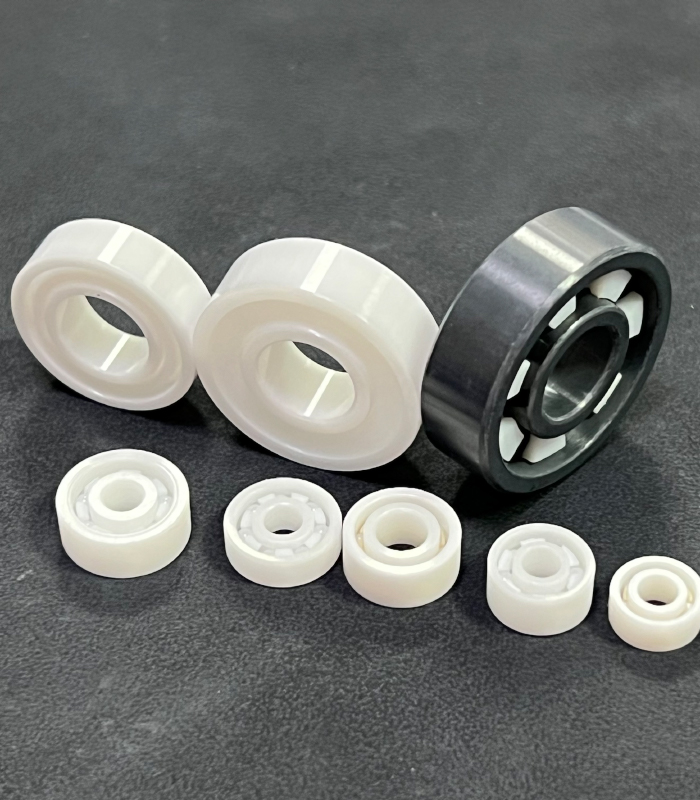

Types of Bearings:ceramic bearings.

1.Introduction to Ceramic Bearings.

Ceramic bearings are one of the most specialized types of bearings. The introduction of ceramic bearings can be traced back to the 1960s when American and Japanese companies developed ceramic bearings successively.

The materials used in ceramic bearings are silicon nitride ( Si3N4 ) and zirconium oxide (ZrO2).

Types of Bearings include full ceramic bearings and hybrid ceramic bearings.

2.Advantages – compared to other bearing materials.

1. Since ceramics have little fear of corrosion, ceramic rolling bearings are suitable for operation in harsh conditions covered with corrosive media.

2. Because the density of ceramic rolling ball is lower than steel, the weight is much lighter, so the centrifugal effect on the outer ring when rotating can be reduced by 40%, and then the service life is greatly extended.

3. Ceramic by the thermal expansion and contraction of the influence than steel is small, so the bearing clearance must be, can allow bearings in the temperature difference between the more drastic changes in the environment.

43 Due to the ceramic modulus of elasticity being higher than steel, the force is not easy to deform, so it is conducive to improving the working speed, and achieving a higher degree of accuracy!

3.Ceramic Bearings – Zirconia or Silicon Nitride?

There are many types of ceramic bearings on the market, all of which offer many advantages over conventional bearing elements. Typical ceramics used as bearing materials are silicon nitride (Si3N4 ) and zirconium oxide (ZrO2 ).

Silicon nitride material advantages:

1. Silicon nitride is a very hard but very light material.

2. It has excellent resistance to water, salt water, and many acids and alkalis.

3, It has a very wide temperature range and is suitable for high vacuum applications.

Silicon Nitride Material Disadvantages:

The very high hardness of silicon nitride also means greater brittleness, so impact or shock loading should be minimized to avoid the risk of cracking.

Silicon nitride has been used as a primary material for a variety of aerospace applications. Notably, NASA’s Space Shuttle was originally made with steel bearings inside turbopumps – not a good combination when the Shuttle, and especially its engines, are subjected to tremendous loads and temperatures.

Because of these extreme loads, NASA engineers upgraded the bearings to silicon nitride equivalents because of their advantages in vacuum environments. Impressively, according to NASA’s analysis, Si3N4 bearings have a 40% increase in runtime compared to steel bearings.

Advantages of zirconium oxide material

1. Ceramic bearings made of ZrO2 or zirconium dioxide are a tough ceramic material.

2, Although they are often referred to as ZrO2 bearings, they are made from ZrO 2 stabilized with yttrium oxide, which gives the material higher strength and fracture resistance at room temperature.

3. Extremely water resistant

Zirconia material disadvantages:

1, have expansion characteristics very similar to steel, although they are 30% lighter. This is an advantage when considering shaft and housing fits for high-temperature applications, where bearing expansion may mean the shaft no longer fits.

2. Being extremely watertight means that they are often used in marine applications, particularly where equipment is fully submerged or where conventional steel bearings are unable to cope with loads or speeds.

Whether to choose zirconia or silicon nitride ceramic materials for bearings? This is always a complex decision. The aspects to consider when choosing a bearing are also multifaceted, but as of now, generally speaking, zirconia ZrO2 bearings are more commonly used because they are extremely corrosion-resistant and tougher.

4.Is it better to choose full or semi-ceramic bearings?

Most of the time when considering the use of ceramic bearings, they are generally thought of as hybrid versions. Hybrid bearings sit in the middle of ceramic and steel and usually include a stainless steel seat or ring and ceramic balls.

For example, we commonly see a 25% increase in revolutions per minute (RPM) on grinding machines by adding ceramic hybrid bearings and synthetic grease due to reduced friction. Grinding spindles with hybrid ceramics can run for up to 4,000 hours without problems, compared to 3,000 hours with steel bearings.

Hybrid bearings can reduce temperatures by nearly 50 percent. On horizontal machining centers, switching from conventional bearings to hybrid alternatives has been shown to reduce bearing temperatures from 60 °C to 36 °C at 12,000 RPM.

Using a hybrid bearing combination allows for higher speeds than the all-ceramic option because the less brittle metal rings are less prone to sudden catastrophic failure at high speeds or under load. That said, the corrosion resistance of hybrid bearings is dwarfed by that of full ceramic bearings. However, there is a market for all-ceramic bearings in more specialized environments.

With the development of technology, the types of bearings will continue to increase.

Maintenance of all types of bearings

If the bearings are found to show signs of failure, there are sand soil and other impurities in the bearings, the lubricant starts to harden and deteriorate, or the bearings run for 2500-3000 hours, the bearings should be cleaned. Regardless of the types of bearings, it requires careful maintenance

When cleaning, the following matters should be noted:

- First remove the old oil in the bearings, then use a brush or cloth dipped in gasoline or kerosene to clean the bearings, at least two times, while also washing the cover of the axial tile and drying.

- Do not rotate the bearings when cleaning, so as to avoid debris pressed into the bearing raceway.

- The bearing cleaned with kerosene should be cleaned with gasoline. Because kerosene contains more moisture, use gasoline to flush away the residual moisture on the bearing to prevent rusting.

- The washed bearings should be wiped dry with a clean wipe, not with cotton gauze, to avoid lint falling into the bearings, and at the same time should not touch the bearings with their hands to prevent the bearings from being stained with perspiration and corrosion, and the wiped bearings can be placed on a clean wooden board or paper to let the residual gasoline or kerosene evaporate.

If there is no obvious shaking of the washed and dried bearings and no spalling of the ball surface, add pure lubricating oil according to the regulations and put the bearings into use again.

Types of Bearings – Service Life

By such factors as manufacturing quality, utilization conditions, load bearing and rotational speed, and other factors together. According to relevant data, the service life of bearings is generally between 2 and 5 years.

These 8 kinds types of bearings are the most frequently used in all kinds of bearings, will you buy bearings? What types of bearings do you need?